Flow Meters

Turbine – Vortex – Coriolis – Ultrasonic – Mag Meter - Oval Gear – Force – Fuel – Nutating Disc

Measuring the flow of fluids and gasses over wide process operational variations has proven to be quite puzzling. Temperature, viscosity’s, velocity, materials of construction, meter accuracy, power requirements and piping arrangements all must be factored into the selection process. Rarely does one type of meter ever fit multiple applications. Modern flow measurement meters are often part of sophisticated electronic control and reporting systems. Selecting the flow meter that best interfaces with the system to generate reliable results requires experience and technical skill.

Meters & Controls has a large selection of devices built by firms recognized as leaders in their device offerings. We have a variety of flow measurement tools for water, steam, inert gasses, fuel gasses, liquid fuels, aqueous and non-aqueous fluid streams. From small 1/8” tubing to 60” diameter water lines we have flow measuring equipment to meet your requirements. To get the flow meter selection process moving please fill in the Flow Meter Fast Track Form as much as possible, or pick up the phone and give us a call. We look forward to working with you on your flow measurement challenges.

Brands Carried

Positive Displacement Meter

Positive Displacement Meter

Liquid Controls M-Series rotary motion positive displacement (PD) meters offer the ultimate in measurement accuracy for custody transfer of petroleum products, aviation fuels, LPG, and a broad range of industrial liquids. LC meters incorporate a unique design, presenting minimal intrusion in a flowing stream of liquid, as well as minimal pressure drop through the meter. The LC meter consists of a housing in which three synchronized rotors turn with no metal-to-metal contact. Hydraulic sealing is accomplished by a stationary boundary layer of liquid, not by the wiping action of mechanical parts

- Low pressure drop.

- Sustained accuracy—no wear from metal-to-metal contact inside the measuring chamber means minimal deterioration in accuracy over time, fewer recalibrations, and longer service life. Meters conform to NIST and International Weights and Measures accuracy requirements.

- Wide temperature range—products can be metered accurately from -40° F (-40° C) to 160° F (71°C).

- Wide viscosity range—LC meters can accurately meter products from less than 30 SSU (less than 1 centipoise) to 1,500,000 SSU (325,000 centipoise).

- Maximum adaptability—right angle design with choice of stock or custom elbows/ fittings provides unequaled mounting flexibility to meet your installation requirements.

- Rated to 150psi / 10.5 BAR.

Electronic Registration

Electronic Registration

Liquid Controls electronic registration has become the standard in the fluid measurement industry. Offering both process control capabilities and absolute accountability in custody transfer processes. The complete solution from Liquid Controls includes a strainer, air eliminator, electronic registration, and volumetric presetting. An electronic register ties all these elements together to ensure the most accurate most reliable system possible.

Mag Flow Meters

Mag Flow Meters

Badger electromagnetic flow meters are designed to achieve ± 0.25 percent accuracy. In addition, the non-intrusive, completely open flow tube design virtually eliminates pressure loss. With no moving parts to impede the flow stream, maintenance is kept to a minimum, even in less than ideal fluid conditions. Available in sizes up to 60” in diameter. Battery Powered models for difficult and remoter locations.

Ultrasonic Flow Meter for liquids

Ultrasonic Flow Meter for liquids

Ultrasonic flow meters are inferential meters that uses ultrasonic technology to measure the velocity of an acoustically conductive liquid moving through it. There are two types of ultrasonic flow meter technologies: Doppler shift and transit-time.

Transit-time measures the time differential between signals sent upstream and downstream. The differential is directly proportional to the velocity of the water. Transit-time meters are best used for measuring the flow of clean liquids and, as a result, are the most popular type of ultrasonic meter. Doppler shift measures the difference in frequency of the sound wave reflected off gas bubbles or particles in the flow stream and is suitable for aerated or dirty liquids.

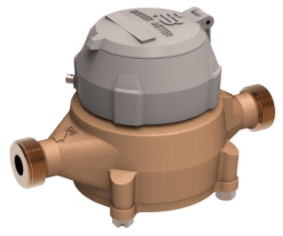

Nutating Disc Water Meter

Nutating Disc Water Meter

Nutating disc meters are the most common and accurate type of positive displacement meters. The simple and reliable operating principle allows water to flow into the chamber, which causes the disc to nutate. Each disc nutation represents a fixed quantity of water, so the total flow is calculated by the total number of nutations.

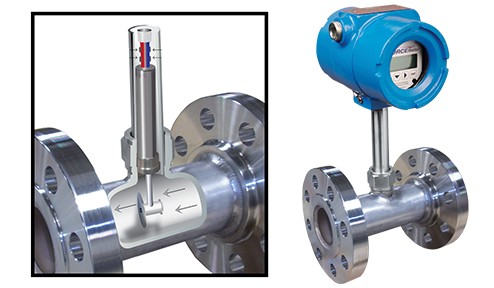

Blancett Turbine Meter with B2800 Flow Monitor

- Displays rate and/or total

- Large 8-digit by 3/4 in. display for easy viewing (meter, remote and swivel mount plus hand-held versions)

- Battery-powered unit uses one “D” size 1.5 volt alkaline battery for up to 3-1/2 years of service

- Loop-powered, 4-20 mA version available

- User friendly front panel programming

- Intrinsically safe (meter, remote and swivel mount versions)

- Microprocessor-based, low power consumption

Oval Gear Meters

The new generation of Macnaught Flow Meters, the MX series, is the revolutionary result of over 47 years’ experience applying Positive Displacement Flow Metering Technology to a variety of industries; all of which insist upon durability, reliability and excellence in performance. Incorporating Oval Gear technology, the MX series is a range of Positive Displacement Flow Meters specifically designed to withstand the rigors of the typical industrial environment, without compromising overall performance. Ranging from sizes ¼” – 4”, and suitable for flow rates from 0.5 lph to 1200 lpm, the MX SERIES offers a complete range of 316 Stainless Steel and anodized aluminum flow meters to suit most any industrial application.

The new generation of Macnaught Flow Meters, the MX series, is the revolutionary result of over 47 years’ experience applying Positive Displacement Flow Metering Technology to a variety of industries; all of which insist upon durability, reliability and excellence in performance. Incorporating Oval Gear technology, the MX series is a range of Positive Displacement Flow Meters specifically designed to withstand the rigors of the typical industrial environment, without compromising overall performance. Ranging from sizes ¼” – 4”, and suitable for flow rates from 0.5 lph to 1200 lpm, the MX SERIES offers a complete range of 316 Stainless Steel and anodized aluminum flow meters to suit most any industrial application.

Flow Meters Fast Track Form

Please enter as much of your application information as you can in the fields below. The more information you can give the faster we can supply an appropriate flow meter solution. If you are unsure of the data requested it is OK to leave it blank.

When you have filled it out as best you can, you can hit submit and the form will be emailed to us. Or you can print it out and fax it to us at 630-279-3844. Once we receive your inquiry we will be getting in touch with you to review your application requirements.

Flow Meter Videos

M-Series Electromagnetic Flow Meters Animation

M-Series Electromagnetic Flow Meters Animation

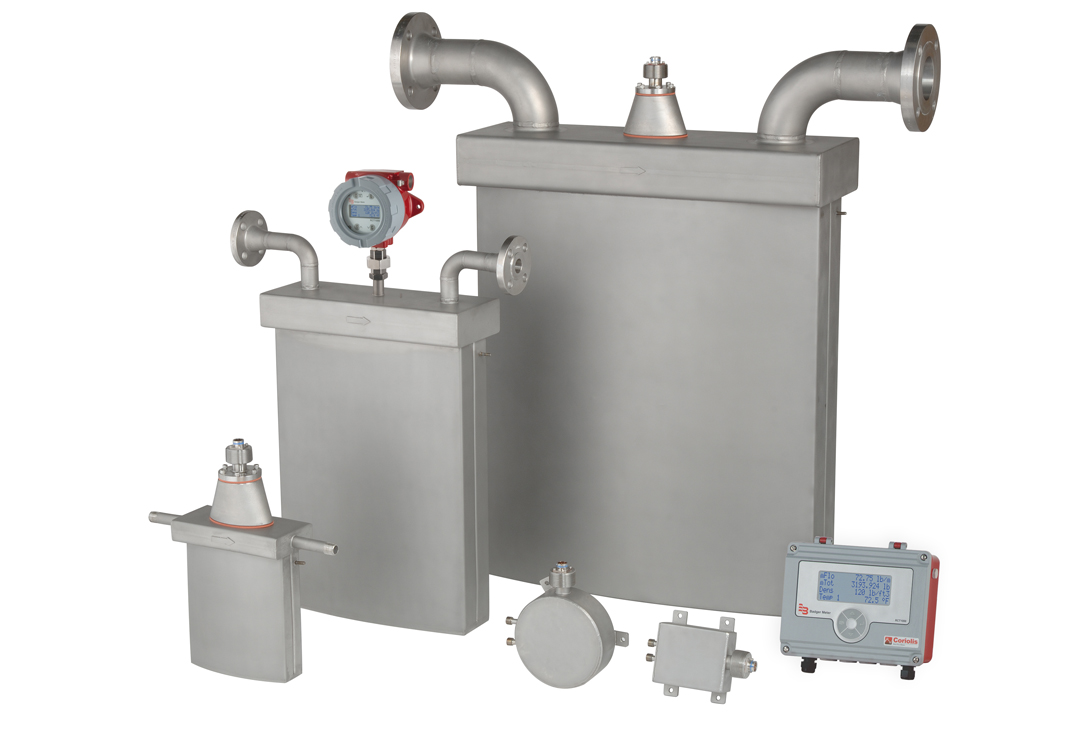

Badger Meter RCT1000 Coriolis Flow System

Strength. Precision. Control. Synergy. These are the hallmarks of a great control system. Each piece working together – accurately and flawlessly. That is what you get with Badger Meter’s RCT1000 Coriolis Flow System – our Mass Flow Meter coupled with our intuitive RCT Console software.

Flow Rate Measurement

Part 1 of the third fluids lecture as part of the module Thermodynamics and Fluids (UFMEQU-20-1), given on 08/11/10.

How Hedland Variable Area Flow Meters Work

Variable area flowmeters.