Filters

Filter Housings, Filter Media, In-Line Strainers

Meters & Controls has a large tool box of filters to apply in solving your filtration applications. To help you sort through the possible tools, to help you understand why and when to use one filtration device or another we offer this basic selection tool as a guide to begin your selection of a solution.

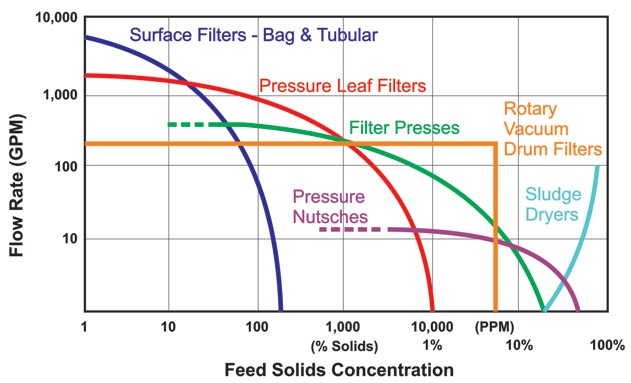

Flows and Loadings by Equipment Type

Filter devices below the blue line are designed for loadings below 200 PPM. Sometimes referred to as polishing filters. Bag, cartridge, tube, pressure screens, strainers and membranes. These can be used at high flow rates as the amount of solids typically are low enough to not clog the piping carrying the fluids.

Below the red line are filters for loadings above 200 PPM but less than 1%. Pressure leaf units, side hill screens, fiber filters, multi plate style and sand filters find applications in this arena of operations.

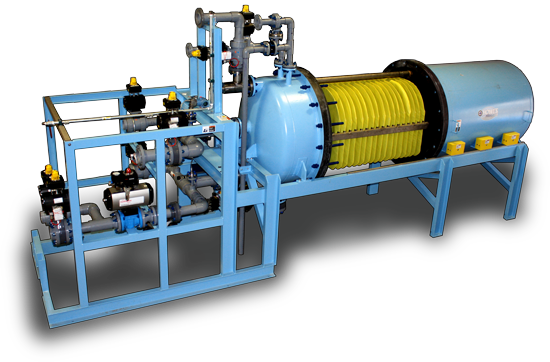

Below the green line are filters that work well with inlet solids greater than 1% up to 12% present in the feed stream. Filter Presses, screw presses, belt filters, vacuum rotary drum filters are often selected for application in this zone.

The orange line represents filters that are designed to operate in a continuous duty operation with loading from a few PPM to around 8% inlet solids where the filter media is diatomaceous earth or cellulose filter aids.

The purple line represents batch filtering of fluids that have up to 40% solids concentration that are dewatered almost exclusively where the solids are the valuable component. Recovery of precipitated crystals or salts is a typical application for these units.

The turquoise line represents a departure from mechanical separation to thermal separation of fluids from non-organic solids. By means of either infrared or indirect steam heating moisture is driven from the solids captured by one of the previous filtration steps. Dry solids content in the high 80 to 90% are achievable in certain applications

To verify selection of a type of filter or drier it is suggested that sample filtration in a lab or onsite use of a rental unit always be considered to confirm operational characteristics.

Please look for the Filtration Fast Track form and fill it out as much as you can. Or pick up the phone and give us a call. We are always happy to help you with your process equipment sourcing.

Brands Carried

Filtration Fast Track Form

Please enter as much of your application information as you can in the fields below. The more information you can give the faster we can supply an appropriate filtration solution. If you are unsure of the data requested it is OK to leave it blank.

When you have filled it out as best you can, you can hit submit and the form will be emailed to us. Or you can print it out and fax it to us at 630-279- 3844. Once we receive your inquiry we will be getting in touch with you to review your application requirements.

Filtration Videos

Kapotek KTF Filter CIP

Automatic self cleaning liquid pressure industry filter

Automatic self cleaning backwash filter Type Filterautomat DDF

Animation Filtration and Backwash.

Installing a Gasketed Filter Cloth on Evoqua’s Filter Press

Dr. D, the filter press doctor, from Evoqua Water Technologies shows us the step-by-step process of installing a filter cloth on a gasketed filter plate for your filter press. Our gasketed plates form a tight seal due to O-rings around the recessed chamber and filtrate discharge eyes, allowing for virtually leak-free operation.

TEKLEEN Mini Twist Filter (MTF Series)

TEKLEEN Minitwist series are low-flow, fully automatic, self-cleaning water filtration systems. These filters can handle flow rates from 1-600 gpm with screens as small as 10µ. The MTF filters use very little water for rinsing so the main flow is not interrupted.

Evoqua Water Tech, What Happens Inside a Filter Press?

Bone-crushing pressures filtering micron-sized particulates inside a machine that nearly every manufacturing process uses - what happens inside a filter press?

Evoqua Water Technologies – Manufacturing Marvels

Learn about Evoqua's manufacturing facility located in Holland, MI where they manufacture filter presses and other water and wastewater treatment equipment.